Vibratory Finishing Tubs – cost effective and absolutely repeatable results

Still today, at many aerospace manufacturing companies, manual deburring and surface edge preparation/smoothing is the method for finishing the surface of very large, heavy and delicate components made of the aluminum, titanium, Inconel etc... It is a fact that such manual work produces somewhat inconsistent surface finishes, it is also very expensive. OEM, MRO and supplier chain aerospace companies are looking for ways to use machines and automate finishing of such components. With its large, medium and small envelope tub vibrators Massfin Aerospace offers a highly effective solution for the automatic finishing of large and heavy single work pieces. Many aerospace applications, from engine, landing gear or structural fuselage parts are processed in tub vibratory machines. Deburring, edge radiusing or machine lines blending/smoothing in vibratory finishing tubs produce repeatable results.

|

Walther Trowal TFM machines are characterized by their robust design and economical purchase price. Very good for aluminum deburring. TFM machines always have U shaped work bowl and equipped with one or two foot motors – life time lubricated!

|

|

Walther Trowal TMV modular machines with specially developed Multivib drive offer processing of very large single parts and also processing of delicate parts which are either clamped with special fixturing devices or processed individually in separate chambers separated by special dividers fitted into tub. This type of process prevent impingement and high value parts damage during the finishing process.

|

|

VKT1 type tub machines are lined with high quality polyurethane with thickness of up to 30mm. All VKT1 type tub machines are designed to treat single part or with use of single or multiple dividers ultimately create independent compartments for single part process (no part on part contact process). VKT1 tubs are equipped with different vibratory drive motors/systems depending on their size and processing channel.

|

|

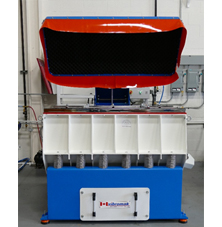

VKT2 type tub machine is equipped with two direct drive vibratory motors, mounted on the side walls of the processing channel/bowl. VKT2 is powerful and flexible machine. Machine is offered with VFD, pneumatically powered sound cover, single or multiple drains, easy to use C shaped channels for installation or removal of dividers.

|

|

VKTO type tub machine is specially designed tub process designed machine with unique round processing channel/bowl. It is used for even deburring and polishing of the part surfaces. O shaped channel allow movement of the media in perfect round circular motion. VKTO is built in 450 lit machine volume.

|