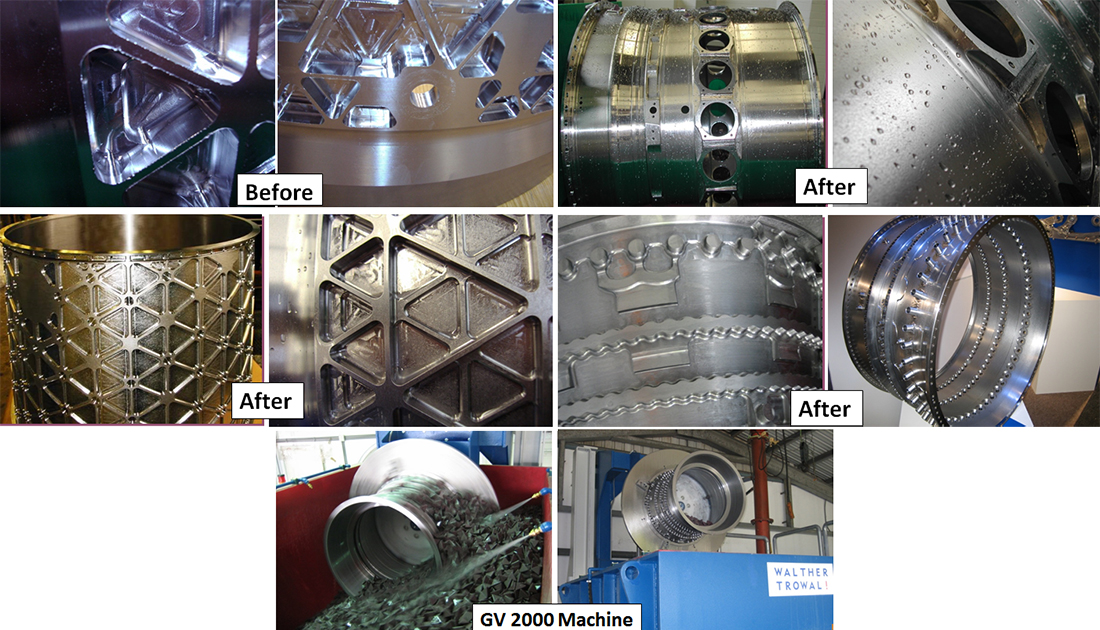

Engine Casing, By-Pass Ducts, Containment Rings etc...

As a customer, you might ask yourself – why those large components are surface finished in Walther Trowal vibratory finishing machines.

These are the reasons:

- Uniform deburring and edge radiusing

- No aria of work piece is "forgotten" to be treated

- Surface quality is same all the time

- Very short process time when compared to manual deburring

- Inner surfaces are deburred at the same time

- Repeatability of process at 100%

- Increased exhaust gas temperature margin (EGT)

- Improved specific fuel consumption (SFC)

- Reduced surface finish roughness on single or multiple components in a range of materials including titanium, Inconel, jet heat steel and other alloys and components.

For more information on GV 2000 machine, please call Branko at 519 965 7034 or e mail to branko@massfinaerospace.com

|